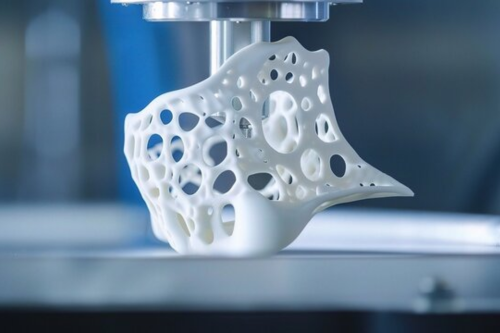

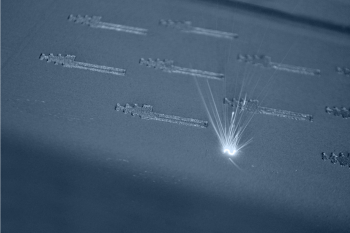

Direct Metal Laser Sintering (DMLS)

Create highly complex and intricate metal prototyping and production parts.

Certifications:

ISO 9001: 2015

|

Get A Free Quote arrow_forwardITAR Registered

Call Us arrow_forwardWhat is DMLS 3D Printing?

Collaborating with Industry Leaders

Why Choose DMLS 3D Printing?

Benefits

» High resolution: .002”–.006” layers

» Highly precise: Product features down to 400 µm and up to 70 cm overall linear dimensions

» Digital workflow

» Cost-effective automated production

Applications

» Tooling and molds

» Low-volume production

» Industrial components

» Medical implants and devices

DLMS 3D Printing Materials

Aluminum (AlSi10Mg)

Ideal for components requiring a combination of lightweight, complex geometries with good thermal properties.

6-8 business days typical lead time

Stainless Steel 316L

Low carbon, non-magnetic stainless steel that exhibits good strength, fracture toughness, and superior corrosion resistance.

6-8 business days typical lead time

Stainless Steel 17-4

High-strength, corrosion-resistant steel with excellent mechanical properties, widely used in molds, medical, and aerospace.

6-8 business days typical lead time

Nickel Alloy (Inconel 625)

Non-magnetic, corrosion and oxidation resistant, nickel-base superalloy, offering outstanding strength and toughness.

6-8 business days typical lead time

Tool Steel (Stainless Steel CX)

High-speed tool steel with excellent wear resistance and toughness, ideal for demanding industrial applications.

6-8 business days typical lead time

Tool Steel (1.2709 Maraging Steel)

18% nickel, cobalt strengthened steel with excellent properties, workability and heat treatment characteristics

6-8 business days typical lead time

Titanium (Ti64)

Lightweight metal with high strength-to-weight ratio, superior corrosion resistance, and biocompatibility, ideal for aerospace and medical.

6-8 business days typical lead time

Copper (CuCrZr)

Copper-based alloy offering excellent electrical and thermal conductivity, ideal for heat exchangers and electrical components.

6-8 business days typical lead time

Copper Alloy (CuCrZr)

Cu-based alloys cover a much wider range of applications than most other alloys due to their functional properties. Typical applications include heat exchangers, electrical and are widely used in bearings.

6-8 business days typical lead time

DLMS 3D Printing Design Guidelines

Maximum Build Volume

10.95″ x 10.95″ x 11.81″ (Stainless Steel 316L, Stainless Steel 17-4PH)

9.92″ x 9.92″ x 11.81″ (Titanium Ti64, Nickel Alloy Inconel 625)

Minimum Wall Thickness

Minimum Feature Size

0.019″ (Copper, Copper Alloy, Nickel Alloy Inconel 625, Stainless Steel 17-4PH, Stainless Steel 316L, Titanium Ti64, Tool Steel)

Leverage DMLS 3D printing for high-quality, cost effective 3D printed parts

Our Other 3D Printing Services

Metal Jet

Medium to high-volume production

Delivers high-strength, production-grade metal 3D printed parts at scale.

MJF 3D Printing

Functional prototyping and low-volume production

Produces industrial-grade, durable plastic parts with excellent surface finish.

SLS 3D Printing

Low-to-mid-volume run with quick turnarounds

Robust, functional prototyping and production for complex components